Stone as Wall Paper: The Evolution of Stone as a Sheathing Material in Twentieth-Century Amman

Introduction

A documentation project carried out in 2000 by the Center for the Study of the Built Environment (CSBE) and the Conservation and Restoration Center in Petra (CARCIP) in association with the ArchNet project.

Funding for this project has been provided by the German Technical Cooperation Agency (GTZ).

Project team:

Fatin Abdullah; Diala Anabtawi; Mohammad al-Asad; Lina As’ad; Aghlab al-Attili; Ala Gammoh; Fady Haddadin; Thaer Haj Ahmad (project coordinator); Hani Imam Hussaini; Kawthar Jeddah; Shadi Jibreel; Miriam Jubeh; Hania Maraqa; Ola Musa; Rula Najati; May Shaer; Hana Sharaf; Ali al-Shibly; Janset Shwash; Shadi al-Yousef; and Samer Younis

This is the first phase of a project that aims at documenting the historical use of stone as a sheathing material for walls in Jordan. This first phase documents twentieth-century Amman, which provides clearly defined locational and chronological parameters. Although Amman has historical roots dating to the earliest pre-historic times, the city was deserted by the fourteenth century to only be resettled in the late nineteenth century. However, almost none of the structures of modern Amman predate the twentieth century. Therefore, this project covers a range that includes Amman’s earliest modern structures as well as its most recent ones.

In dealing with stone as a sheathing material, the following database primarily aims at providing both textual and visual information on the dressing of stone and the patterns created by it. Also, we have provided additional information such as the locations of the structures being documented, their dates, and their architects. A few explanatory notes should be given about such additional information. The locations include both the area in which the structure is located and the street address for it. Such information helps one locate the structure in relation to the city, and also allows one to visit it. However, street addresses are not widely used in Amman and there were a few cases for which we were not able to locate street numbers for the structures being documented. In such cases we only provided the street names.

Concerning dates, which allow us to tie the samples together chronologically, we have provided the decades to which these buildings belong since such structures usually have been built over a period of a few years. In many cases, we were able to obtain specific dates for these structures. However, in some cases, such specific dates were not available since the original residents or owners could not be located, or the documents that might provide such dates were not available to us. In such cases, we were able to estimate the dates for the buildings through a number of means including the location of the building in the city since different parts of the city were developed at certain periods. We also depended on examining the architectural features of the structures, which usually give sufficient information about the period to which they belong. In general, we believe that the results we have obtained for the dates are reliable, but when in doubt concerning the dates, we have indicated that they are approximate in nature.

Concerning architects, we have provided the names of the architects whenever they were available to us. In this context, it should be kept in mind that the earlier structures in Amman were not designed by architects, but by the builders themselves, and no documentation usually exists concerning the identities of these builders. In fact, it was not until the 1950s, and the founding of the Jordanian Engineers Association (to which architects in Jordan belong) that architects began to be more fully entrusted with the design of structures in Amman. Of course, whenever new or more specific information becomes available concerning street addresses, dates, or names of architects we will add that information to the database.

The documentation for this project includes an article by May Shaer that provides information on the evolution of the use of stone in Amman as a sheathing material for buildings, and on the various tools and methods used in the dressing of stone. Also, definitions of the various Arabic terms used for different types of stone dressing can be found in this article. As for the database, it includes over eighty samples with textual data and an image for each sample. The database is searchable and can be organized according to the various entries it includes such as dates, type of stone dressing, arrangement of stone blocks, … etc.

We hope that this project will be of considerable benefit for architects, clients, researchers, and students interested in stone. We are working on developing and expanding the project’s database and we welcome any comments that its users might have about it.

We would like to thank Dr. Helge Fischer, Project Director, Petra Stone Project – GTZ for the considerable support he has provided for this project.

The Use of Stone in Amman

May Shaer, Conservation Architect, Conservation and Restoration Center in Petra (CARCIP)

Introduction

Stone has been widely used in building in Jordan since pre-historic times. It has evolved from being a load bearing construction material to one that is merely used for cladding buildings and therefore serves aesthetic purposes. Although each historical cultural period reflects individual building techniques, there are many traditions in the cutting and processing of stone that have been carried on from antiquity to the present day.

The following database provides a compilation of building surface patterns composed of stone in various designs, and is the result of a survey of the use of stone in buildings. The database is by no means comprehensive and currently only includes the variety of tool marks and patterns from structures that are found in the city of Amman and span the period of the twentieth century. It is hoped that the database will continue to grow and will eventually include patterns found in other parts of Jordan and will cover earlier periods.

The Use of Stone in Amman

Introduction

One of the first characteristics that strike the visitor to Amman is that the city is composed of white blocks arranged in various combinations. Except in very few cases, limestone is the material used for cladding facades, and it is what gives Amman, the capital city, its unique homogeneous character.

However, looking closely at the buildings, one begins to notice a variety of patterns formed by the stone blocks themselves and determined by their color, tool marks, size and arrangement. The limited flexibility, color and workability of limestone has contributed to a variety of wall patterns that reflect the individual style of the owner of a building, the architect, or both. These patterns often maintain a sense of austerity.

The Quarries

A variety of different stone formations can be found in Jordan that includes types such as limestone, granite, sandstone and basalt. Until now, limestone is the most quarried and used type of stone in Jordan. It is found in different parts of the country in a variety of color ranges: white, yellow, gray, brown and red. It is also exported to other countries in the region, either as a raw material or as a finished, cut and dressed product. Additionally, some buildings in Jordan have employed stone brought from Palestine, which includes some of the best known quarries in the region. Of these are the Jama’in quarries close to the city of Nablus, which provides white, hard limestone.

As for the Jordanian quarries, nowadays limestone is being quarried in the areas of Ma’an, ‘Ajlun, Irbid, al-Azraq, and the desert plains. The quarries of Ma’an, located in the southern part of Jordan, are famous for their white hard limestone, which is classified as a first grade stone, due to its hardness, purity and low porosity. Additionally, we find that some of the quarries of Ma’an produce another type of limestone that is of lower quality and has a darker beige color and yellow veins. ‘Ajlun, in the north of Jordan, has white limestone quarries of high strength, while the quarries of Irbid produce white and reddish colored limestone in addition to black volcanic rock. The “desert stone” is a white and reddish limestone that comes from the area of al-Azraq east of Amman, along the edge of the desert areas. Finally, the quarries found in the area of Salt near Amman produce soft limestone in white and yellow colors.

Stone Surface Treatments

By using a variety of tools in working the surface of stone, several different textures can be generated. Additionally, the exposed surface of the stone is sometimes intentionally left untreated or is treated by methods other than carving with conventional tools. The following are the different ways in which stone surfaces are found on building facades, most of which are given their local Arabic terms (other terms are also used, though for some there is no consensus regarding what they actually designate):

1. Rubble: This represents pieces of stone used in their natural state.

2. Shuhaf: These are leftover pieces of stone that remain after cutting stone blocks. They are relatively thin slabs of irregular edges but have a smooth surface as a result of cutting the stone with an electric diamond saw. Marks of the saw are often apparent on the surface of the stone.

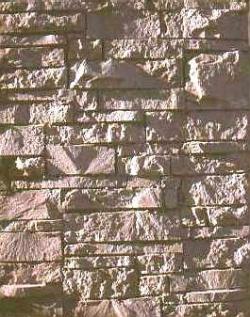

3. Untreated: This represents stones that expose their natural surface after being detached as a whole geologic layer from the stone quarry. In this case, only the two sides that were in contact with the other layers are utilized and cut out of the slab to be used for cladding. The stone in between the outer surfaces is not used.

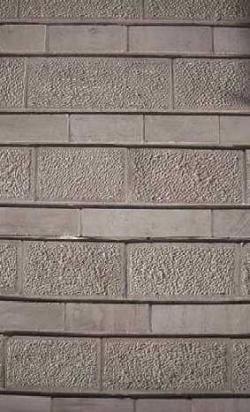

4. Split surface: This is when a cut block of stone is split in the middle. The surface used for facing is the one that was split. It shows a roughly textured, not very protruding surface. For that, a large sized pitching tool (Tumbor) is used with a single stroke.

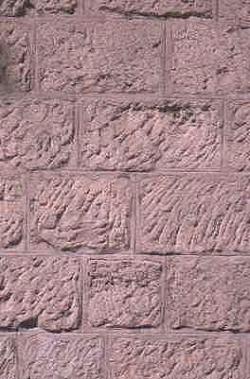

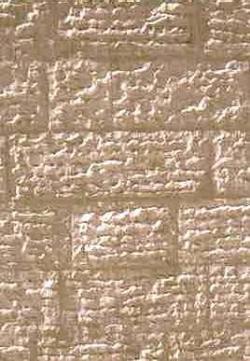

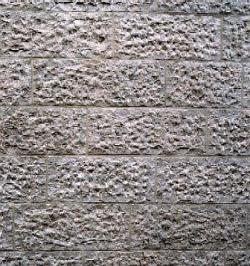

5. Tubzeh: This is a roughly dressed surface of the stone. It is done by having a relatively thick stone with a protrusion of about 5cm from the surface. Small pieces are then split or chipped out from the surface with a pitching tool (Tumbor).

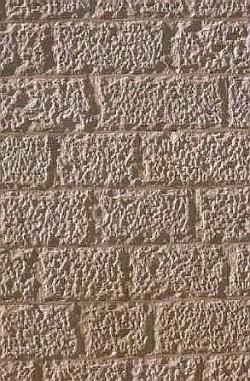

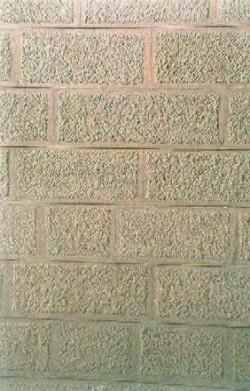

6. Mufajjar: This is a dressing of medium roughness. It is done with a point chisel (Shawkah) hammered on the stone surface with single strokes, creating a speckled surface.

7. Mufajjar Matari: This is a dressing of parallel lines created with a point chisel and is done by following a line on the stone with the chisel held at a 45&Mac176; angle and without lifting it from the surface.

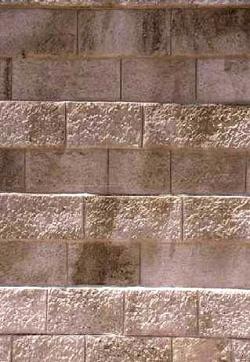

8. Musamsam: This is a dressing of a series of short, fine parallel lines, done with a tooth chisel.

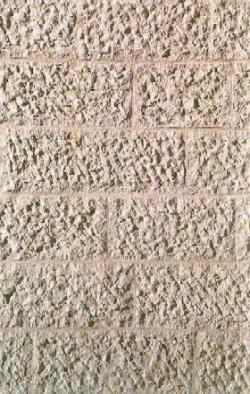

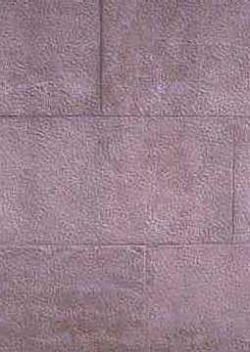

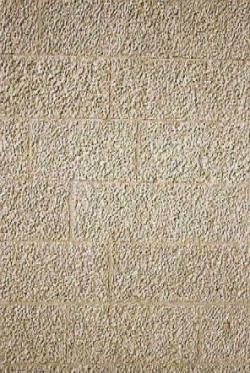

9. Mattabeh: This is a finely speckled surface dressed with a bush-hammer (Mattabeh). Nowadays, a mechanical version of the bush hammer is also used.

10. Saw-cut: This represents slabs of stone cut with an electric diamond saw and left undressed. Engraved circular lines resulting from the use of the electric saw can be found on such stone surfaces.

11. Polished: This is traditionally done with a scraper (Shahuta), whereby the scraper is passed across the stone surface back and forth until a smooth surface is achieved. Nowadays, a very smoothly polished surface can be achieved with special polishing machines. A rougher polished surface can be achieved through sand blasting.

12. Flamed: This is a roughly textured surface that can be achieved by passing a flame over the stone or marble surface causing the grains to burst.

13. Barrel-shaped: This represents stone pieces cut as half cylinders which are placed next to each other in horizontal or vertical courses. They in turn can be dressed as Mufajjar or Musamsam surfaces.

14. Zamleh: This is a frame that is sometimes found on stone blocks framing the dressed surface. It can be found along one or more of the edges of the stone. A flat chisel (Izmil) is traditionally used to create such a frame.

Chronological Evolution of Wall Surface Treatments and Wall Patterns

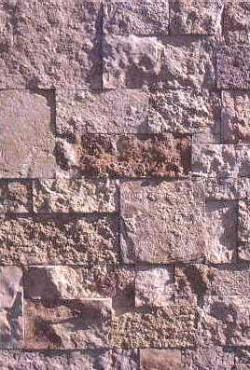

From the wall samples surveyed, it appears that buildings constructed up to the 1920s and 1930s primarily had their stones dressed in the Tubzeh manner, and arranged in 25cm horizontal courses, often with a 0.5cm white/beige pointing. Sometimes, rubble is used, whereby the joints are irregular and unpointed.

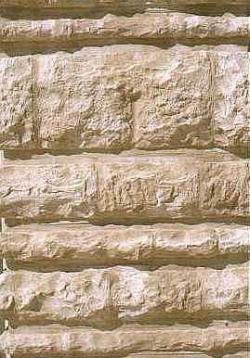

Moving on to the 1940s, the Musamsam surface seems to predominate, though the Tubzeh dressing remains widespread. Also, the black recessed pointing that defines the stone blocks becomes more popular than the previously used flush pointing. We also begin to notice a variation in the arrangement of the 25cm horizontal courses, where, for example, protruding and recessed courses are used in an alternating manner.

In the 1950s, the smooth flat Musamsam surface of the as well as the rough rustic Tubzeh dressed surfaces of the stone could still be found. Additionally, we find polished surfaces. Pinkish-white as well as yellow colored stone is also used. The horizontal courses are 25cm high and the black recessed pointing predominates.

The Musamsam and Tubzeh dressing continued to be used on buildings of the 1960s. However, we begin to notice more attempts in creating different wall patterns. For example, within one wall the two types of dressing can be found, or different colored stones are used in one façade by forming courses of alternating colors. Additionally, we find a variety of heights of courses within one façade, or alternating protruding and recessed courses. Sometimes there are differently colored and irregularly shaped stones. Still, the thin black recessed pointing predominates. Attempts to use different types of stone to clad façades begins to appear – such as thin marble slabs.

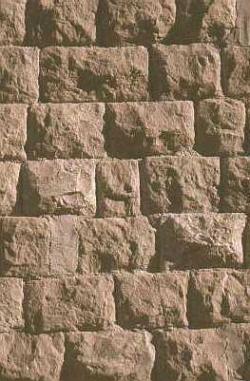

During the 1970s, new patterns begin to be frequently used, such as the regular grid arrangement of Musamsam blocks or the random grid formed of Tubzeh blocks of different sizes and having a flush 2.5-3cm thick black pointing, creating a rustic impression. We also find a variation of the recessed black pointing used earlier on facades with horizontal courses, where now it can appear as a recessed 2.5cm thick pointing in the horizontal direction, while the vertical one remains a 0.5cm thick recessed pointing. We also find combinations of differently dressed stones in a single façade, such as Tubzeh and Mattabeh, and Musamsam and Saw-cut. Vertically arranged courses can also be found.

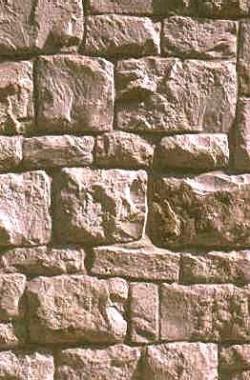

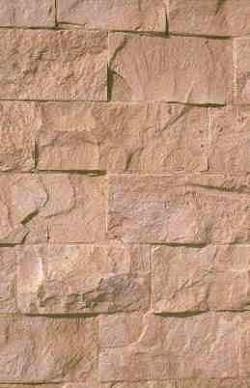

In the 1980s, though previously used textures such as the Tubzeh and Musamsam were still used, a new type of surface dressing began to become widespread, which is the Mufajjar. This is a dressing with a medium roughness – between the Tubzeh and Musamsam. It is created by hitting the point chisel with a hammer, and depending on the angle at which the chisel is held, either a speckled surface, a surface with short lines or one with long parallel lines (the Matari version) is created. The Mufajjar dressing seemed to provide a solution for achieving a roughly textured surface without the need for the thick stone blocks required by the Tubzeh dressing. It is mainly arranged in 25cm horizontal courses with a 1cm white pointing.

The Tubzeh dressing can also be found dressing dark beige, yellow and white stone in buildings of the 1980s. Because the Tubzeh dressing requires quite thick stone blocks, and is predominantly achieved through manual craftsmanship that substantially adds to the cost of a building, it begins to be found associated with other types of dressing. In addition to the 25cm high horizontal courses, it can also be found in courses of alternating different sizes, as an arrangement of equally sized blocks in a regular grid, or as a randomly arranged grid. Although the black pointing can still be found, the white 1cm thick pointing begins to predominate. The split surface stone begins to be used in combination with the Tubzeh dressing as rectangular blocks of different sizes, and arranged in random horizontal courses thus creating uneven façade surfaces.

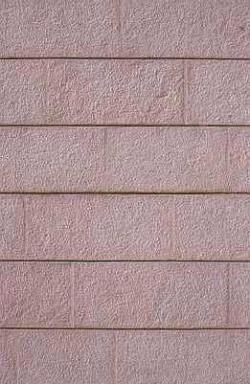

Finally, in the 1990s we find attempts to break with the traditional 25cm height of the horizontal courses. The 50cm high horizontal course gains popularity, particularly by the end of the 90s, with the Mufajjar and the machine bush-hammered Mattabeh dressing applied to it. We can even find an arrangement of 50x100cm stone in a regular grid, with hardly any joints appearing. Also, 20cm and 40cm high courses can be found. Nevertheless, the 25cm course height still predominates, along with the various types of dressing and the 1cm white pointing, though the recessed black pointing can still occasionally be found. Occasionally, the stone blocks are framed with a Zamleh, sometimes arranged in vertical courses or regular grids.

Barrel-shaped blocks, which began to be popular in the 1980s, continued to be increasingly used in the 1990s, in different types of dressing. Moreover, we find during this period attempts to also break with the traditional types of surface dressing, whereby polished surfaces as well as untreated and split surface stone become increasingly used in random grid arrangements. We also find an example of flamed granite covering the exterior walls of a commercial building.

From the surveyed samples, it can be noted that although traditions in the use of stone in Amman continued throughout the century, there is an evolution in its presentation, whether in the stone texture, proportions or patterns. In external fences we find the most experimentation, as with the use of non-uniform stone blocks, while in commercial buildings we find more experimentation in using polished types of stone (limestone, marble, granite) and employing larger dimensions of stone blocks.

References on Quarries and Methods of Stone Cutting

Abusaud, S.A. 1988 The Right Way to Build with Stone. Amman: Ministry of Culture.

Rockwell, P. 1993 The Art of Stoneworking. Cambridge: Cambridge University Press.

Stone Samples: